Sputtering

2022-08-17581Vacuum Evaporation Recap

• Use high temperatures at high vacuum to evaporate (eject) atoms or molecules off a material surface.

• Use ballistic flow to transport them to a substrate and deposit.

• Film uniformity can be an issue.

• Alloy evaporation is very complicated and in most cases, not possible.

An Alternative Method

• Instead of using heat to eject material from a source, we can bombard them with high speed particles.

• The momentum transfer from the particles to the surface atoms can impart enough energy to allow the surface atoms to escape.

• Once ejected, these atoms (or molecules) can travel to a substrate and deposit as a film.

• There are several considerations here: – Creating, controlling and directing a high speed particle stream.

– Interaction of these particles with the source surface and emission yields.

– Deposition of the emitted atoms on the substrate and film quality.

Some Terminology

• Atomic particles can best be easily controlled by electromagnetic methods if they are charged. A weakly charged gas of particles that exhibit collective behavior is called a plasma.

• The source material is called the target and the emitted atoms or molecules are said to be sputtered off.

Sputtering

• So in sputtering, the target material and the substrate is placed in a vacuum chamber.

• A voltage is applied between them so that the target is the cathode and the substrate is attached to the anode.

• A plasma is created by ionizing a sputtering gas (generally a chemically inert, heavy gas like Argon).

• The sputtering gas bombards the target and sputters off the material we’d like to deposit.

Generating and Controlling the Plasma

• Ions can be generated by the collision of neutral atoms with high energy electrons.

• The interaction of the ions and the target are determined by the velocity and energy of the ions.

• Since ions are charged particles, electric and magnetic fields can control these parameters.

• The process begins with a stray electron near the cathode is accelerated towards the anode and collides with a neutral gas atom converting it to a positively charged ion.

• The process results in two electrons which can then collide with other gas atoms and ionize them creating a cascading process until the gas breaks down.

• The breakdown voltage depends on the pressure in the chamber and the distance between the anode and the cathode.

• At too low pressures, there aren’t enough collisions between atoms and electrons to sustain a plasma.

• At too high pressures, there so many collisions that electrons do not have enough time to gather energy between collisions to be able to ionize the atoms.

Glow Discharge Formation

• Initially the current (charge flow) is small. As charges multiply the current increases rapidly but the voltage, limited by supply, remains constant.

• Eventually, there are enough ions and charges for the plasma to be self-sustaining.

• Some of the electron-atom collisions will produce light instead of electrons and ions and the plasma will also glow accompanied by a voltage drop (normal glow)

• If the input power is increased further, the current density becomes uniform across the cathode and we’ll be in the abnormal discharge regime. This is where sputtering operates.

Plasma Pressures

• Unless there are enough collisions, the plasma will quickly die.

• In order to have a self-sustaining plasma, each electron has to generate enough secondary emission.

• Since we want collisions to occur, the pressure can not be too low. – The mean free path should be a tenth or less than the typical size of the chamber.

• Also, since we want the electrons to gain enough energy between collisions, the pressure can not be too high.

• This means discharge tube pressures around 10-1000 mTorr and plasma densities around 1010 – 1012 cm-3.

Ion-Surface Interactions

• When ions bombard a surface, several things can happen:

– Reflection

– Sticking (adsorption)

– Sputtering

– Ion implantation

– Chemical reactions

– Electron and photon emission

• The ion beam energy is the critical parameter.

– < 5 eV : Adsorption or reflection

– 5 - 10 eV : Surface damage and migration

– 10 - 3 keV : Sputtering

– > 10 keV : Ion implantation

How Ions Sputter Atoms

• When ions collide with surface atoms on the target, the energy transfer can knock some of these atoms off the surface.

• The key principle is energy and momentum conservation.

• In any collision, momentum is conserved.

• If the collision is elastic, kinetic energy is also conserved.

• The energies required for sputtering are much higher than lattice bonding or vibrational energies (which are the causes of inelastic interactions), therefore sputtering collisions can be considered elastic.

Deposition

• Sputtered atoms from the target make their way on to the substrate through diffusion.

• Ions and neutralized gas atoms may also embed on the substrate as impurities.

• The ions incident on the substrate may also re-sputter the surface.

• Chemical reactions may occur.

Deposition Rate

• It is proportional to the sputtering yield.

• An optimum pressure exists for high deposition rates.

– Higher pressure means more collisions and ions.

– Lower pressure means less scattering.

Alloy Composition Issues

• If a target is made up of several atoms with different sputtering yields, initial film composition can be off.

• However, sputtering yield variations are smaller compared to vapor pressure variations. Therefore the

initial layers of film will be more closely related to the target composition.

• Also, since temperatures are lower and melting is not an issue, diffusive homogenization at the substrate is less likely.

• Finally, any initial disparities will eventually correct themselves as the amount of the faster sputtering

component at the target reduces.

Compound Issues

• While most of the previous discussion is applicable to compounds there is an interesting issue.

• If the target temperature is too low, ion bombardment can result in amorphization of crystalline targets and isotropic sputtering.

• Increasing the target temperature anneals the surface as it sputters, thereby keeping the crystalline structure and a more directional sputtering.

Some Parameters

• Argon Pressure

– optimum deposition rate around 100 mTorr

– compromise between

• increasing number of Ar ions

• increasing scattering of Ar ions with neutral Ar atoms

– if you can increase the number of ions without increasing the number of neutrals, you can operate at lower pressures

• Sputter voltage

– maximize sputter yield (S)

– typically -2 to -5 kV

• Substrate Bias Voltage

– substrate is being bombarded by electrons and ions from target plasma

• sputtering film while you deposit

– neutral atoms deposit independently

– put negative bias on the substrate to control this

– can significantly change film properties

• Substrate temperature

– control with substrate heater

– heating from deposited material

• increases with increasing sputter voltage

• decreases with increasing substrate bias

• Particle Energy

– increases with increasing sputter voltage

– decreases with increasing substrate bias

– decreases with increasing Ar pressure

Advantages

• Not a line of sight method

– Can use diffusive spreading for coating

– Can coat around corners

• Can process alloys and compounds.

– High temperatures are not needed

– Even organic compounds have been sputtered.

• Can coat large areas more uniformly.

• Large target sources mean less maintenance.

-

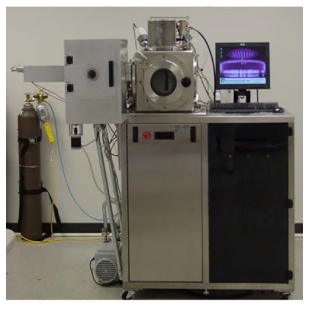

- 磁控溅射真空镀膜机 NSC-4000(M)磁控溅射系统 那诺-马斯特

- 品牌:美国那诺-马斯特

- 型号:NSC-4000(M)

-

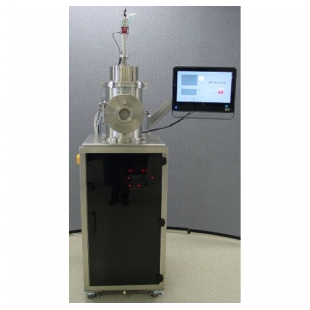

- NSC-1000磁控溅射系统 那诺-马斯特 磁控溅射镀膜厂家

- 品牌:美国那诺-马斯特

- 型号:NSC-1000

-

- 离子溅射仪 NSC-3000(M)磁控溅射系统 那诺-马斯特

- 品牌:美国那诺-马斯特

- 型号:NSC-3000(M)

-

- 磁控溅射镀膜机 NSC-3000(A)全自动磁控溅射系统 那诺-马斯特

- 品牌:美国那诺-马斯特

- 型号:NSC-3000(A)

-

- 磁控溅射设备 NSC-3500(M)磁控溅射系统 那诺-马斯特

- 品牌:美国那诺-马斯特

- 型号:NSC-3500(M)

-

- 磁控溅射镀膜机 NSC-3500(A)全自动磁控溅射系统 那诺-马斯特

- 品牌:美国那诺-马斯特

- 型号:NSC-3500(A)

-

- 磁控溅射镀膜设备 NSC-4000(A)全自动磁控溅射系统 那诺-马斯特

- 品牌:美国那诺-马斯特

- 型号:NSC-4000(A)