一、180°剥离试验机概述General Description:

该款剥离试验机根据GB/T2611-2007《试验机通用技术要求》和GB/T16491-2008《电子式wan能试验机》标准制造。计算机全自动控制设备的上升、下降、试验、停止等,设备外形美观、操作方便、性能稳定可靠。

The model is designed and developed as per

GB/T2611-2007《General technical requirements for testing machines》

GB/T16491-2008《Electronic Universal Test Machine》

Automatic control by computer to some action like up,down,test,stop and some work,

It has some features like elegant design,simple operation,and stable performance.

二、180°剥离试验机用途Description of Function:

该系列产品主要用于1000N以内的拉伸、剥离、撕裂等试验。广泛应用于航天航空、石油化工、机械制造、塑料橡胶、陶瓷建材、金属材料、建筑工程等行业,以及高等院校、科研机构、技术监督、质检站所等部门。

The Computerized 180°Peeling Tester applies to products performing the mechanical tests of stretching,peeling,and tearing,etc within the range of 1000N.Widely in some applications like Aerospace,petrochemical,machinery manufacturing,plastic rubber,ceramic building materials,metal materials,building engineering,also in College and Universities,Scientific and Research Unit,Technical Supervision,quality Inspection Station.

三、主要技术参数Main Technical Specification:

产品型号Model:

YC-180-BL(很大试验力Max Capacity:1000N)

1试验力Test Force

很大试验力Max Test Force(N):1000N

试验机测量精度Measuring precision:0.5级Grade 0.5(标准版Standard Version)

有效测力范围Valid Measuring ranges:2%FS/

分辨力Solutions:1/300000

示值相对误差Error of Indicating value:±1%

2试验速度Test Speed

速度调节范围:0.001~500mm/min(无级调速)

Range of adjusting speed:0.001~500mm/min(Variable)

力控速率控制范围

Controlling ranges of force rate:0.005—5%FN

力控速率控制精度:速率<0.05FN/s时,为±2%设定值以内;

速率≥0.05FN/s时,为±1%/设定值内

Accuracy of controlling rate:within±2%of set value,speed<0.05FN/s

within±0.1%of set value,speed<0.05FN/s

变形速率控制范围Controlling ranges of deformation rate:0.005—5%FN;

变形速率控制精度:速率<0.05FN/s时,为±2%设定值以内;

速率≥0.05FN/s时,为±0.5%设定值内

Controlling accuracy of deformation rate:within±2%of set value,speed<0.05FN/s

within±0.1%of set value,speed<0.05FN/s

3位移(移动横梁)Displacement(Crossbeam moving)

测量范围Measuring ranges:0~500mm

分辨率Resolution:0.001mm

电池片拉伸测试仪测量精度Measuring accuracy:better than±1%of indicating value

4试验空间Test Space

有效测试空间Effective Testing space:500mm(or customized)

5工作环境:室温10~35℃,湿度20%~80%

Working conditions:RM+10~35℃,Humidity:20%~80%

五、结构特点Some features in Machine Structure:

1.主机Load Frame Machine:

1.1该机采用桌上型卧式结构,采用伺服电机驱动,伺服电机通过传动机构带动移动横梁左右移动,实现试验加载过程。

1.1 The machine adopts a desktop horizontal,equipped with servo motor,which can drive he moving beam to move left and right through the transmission mechanism to realize the loading test process.

1.2圆弧同步带轮和滚珠丝杠副传动是平稳的无间隙传动,从而得到试验力和变形速度精密控制,传动平稳,响应快,噪声低。

1.2 Arc tooth synchronous belt gear and ball screw rods as subsidiary transmission,is smooth and no-seal transmission,to reach accurate controlling to the speed of test force and deformation,smooth transmission,fast response,low noise.

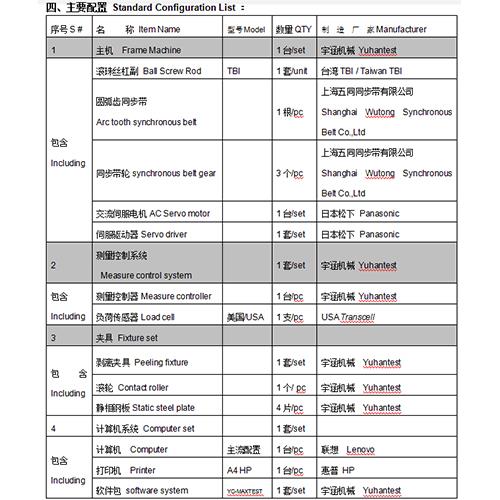

2.附具:标准配置:180°剥离附具一套,滚轮一个,静相钢板四片。

Accessories:Standard list:180°peeling fixture,contact roller and static steel plate.

3.传感器扩展配置:支持2个力传感器,用户可根据需要随时更换;

Extension function of load cells:support 2 sets force cell,you can choose your list at your need.

六、软件功能特点Function and Features in the software system:

1.自动清零:试验开始启动后,系统自动清零;

Auto Zero:after the test start,the system do auto zero.

2.自动标定:系统可自动实现示值准确度的标定;

Auto calibration:Auto calibration of indicating vale in the system.

3.自动返回:实验结束后,横梁自动返回至初始位置;

Auto back,after finishing the test,crossbeam will be back to initial place automatically.

4.自动换档(当选择分档测量时):根据负荷大小自动切换到适当的量程,以确保测量数据的准确性;

Auto shift-gear(when you choose different measuring gear),it can do automatic shift as per the different load capacity for better accuracy.

5.自动变速:试验过程中移动横梁的速度可按预先设定的程序自动变化,也可手动变化;

Auto transmission:the speed of crossbeam is processed by automatic or hand.

6.自动保存:采用数据库管理方式,试验结束,试验数据和曲线自动保存;

Auto Save:in the database,it can save test data and curves after the test is over.

7.自动计算:试验结束时自动计算弹性模量、屈服强度、非比例伸长应力等(试验方法不同,分析的数据也会不同),可以自动分析,还可以人工修正分析结果,提高分析的准确性;

Auto Calculation:auto calculation and analysis of test data like Elastic modulus,yield ratio,and Non proportional elongation stress.(different test methods,the data analysis is different),you can choose automatically analyze,also can analyze the results of manual correction to improve the accuracy of analysis;

8.显示方式:数据和曲线随试验过程动态显示;

Display Mode:Realize real time display for test data and curves.

9.结果对比:多条试验曲线可用不同颜色叠加、再现、放大、呈现一组试样的对比;

Result comparison:multi-curves can be superposition,reproduction,amplification,showing a comparison of a set of samples;

10.曲线选择:可根据需要选择应力-应变、力-位移、力-时间、位移-时间等曲线进行显示和打印;可随时切换观察,任意放大缩小,水平或垂直移动,实时高速采样;

Curve choice:Stress-Strain,force-displacement,force-time,displacement-time curve are displayed and printed change different curves,enlarge or small at needs,horizontal or vertical movement,real time sampling at fast speed.

11.批量试验:对相同参数的试样,一次设定后可顺次完成;

Bulk tests:testing sample as per preset series on the same parameter.

12.试验标准:集成了近四十种地域标准或试验方法,可以满足客户的多方面试验的需要;

Test standard:integrated more than 40 National standard or test method,to meet different need in different industrial ranges.

13.数据查询:可对历史试验数据进行查询,只需输入一定的条件,试验数据立即找到;

Data inquiry:you can check test data in the database,data can be found as per simple key

words or test No.

14.测试过程:试验过程及测量、显示、分析等均有PC机完成;

Measuring process:Test procedure,Measurement,Display,Analysis are done by computer.

15.试验报告:可按用户要求的格式编制报告并且可以打印批量数据;

Test Report:you can edit Test Report Form at need,and print test report in bulk.

16.限位保护:具有机械和程控两级限位保护功能;

Limit Position Protection:equipped with mechanical and program control

17.过载保护:当负荷超过各档很大值的3-5%时,自动停机

Over-load protection;when test load exceed 3%-5%of Max vale in each gear,the machine will stop working.

18.其它保护:具有过载、过流、过压、位移上下限位和紧急停止等保护功能

Other protections:over-load,over-pressure,over-current,up and down limit position protection,Emergency stop button,and protection functions

七、技术情报和资料的保密Confidential in Technical documents

本技术方案属于我公司技术资料,用户应对我方提供的技术情报和资料承担保密义务,不论本方案是否采用,本条款长期有效;

The Technical Recommendation List belong to commercial and technical documents in our company,the user have to keep confidential duty to documents,whatever you will buy or not,the terms is in long and confidential right.

我方对用户提供的技术情报和资料亦应承担保密义务。

We will keep the confidential duty to user information,

上海宇涵机械有限公司

仪器网(yiqi.com)--仪器行业网络宣传传媒