企业性质生产商

入驻年限第5年

在工业质量控制和材料研究方面,您和您的团队有着相同的目标:提供信心百倍的可靠结果。通过有助于日常任务的软件,令您的团队工作速度更快,效率更高,结果更jing准。来自 Leica Microsystems 的 Leica Application Suite X (LAS X) 是工业应用中进行直接成像和记录的软件平台。

使用独有的全屏图像专注于您的样品

根据您的需要显示和展开功能按钮

为您的测试程序定制报告模板

设置单独的用户配置文件,根据操作员技能配置显微镜和摄像头

软件可更快速、更轻松、更高效地执行标准任务;同时并不复杂。LAS X 拥有整洁的用户界面和导航,使工作流程清晰直观,任何团队成员都能轻松掌握。

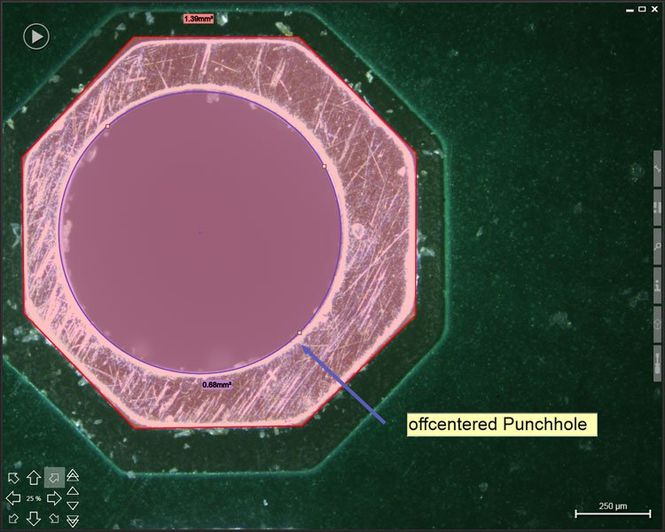

全屏查看样品:

使用全屏尺寸专注于样品 — 功能按钮在不需要时透明化

单击鼠标即可激活功能按钮 (例如照明设置、摄像头、测量)

自动保存功能让您充满信心,绝不会错失任何细节

LAS X software platform fullscreen mode

LAS X software platform fullscreen mode

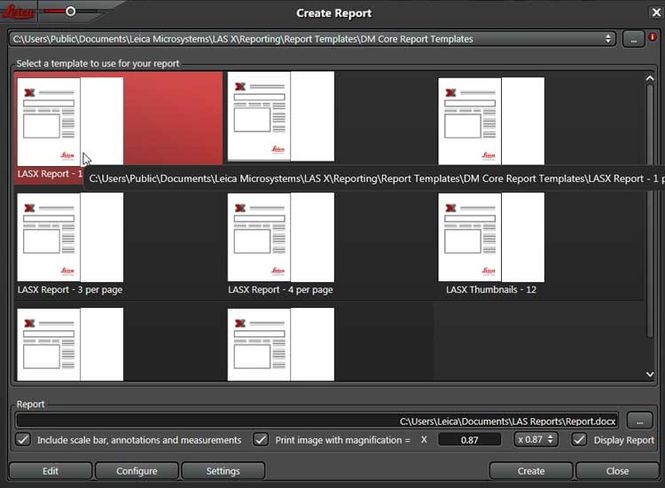

LAS X 为您提供丰富的报告模板。

此外,您还可根据自己的需求定制模板,并与您的团队共享。这样可以确保您的团队提交一致的报告。创建可靠的测量结果报告,从未如此简单。

为测量结果创建可靠的报告从未如此简单。

报告导出,一键完成!

可对报告模板进行调整,以适用于您的测试程序

Report templates of LAS X software platform

保存和调用

工作的可再现性对于许多应用都非常重要。

切如此简单,只需一次单击,即可轻松再现之前的显微镜设置和成像参数。

Upright material microscope Leica DM6 M

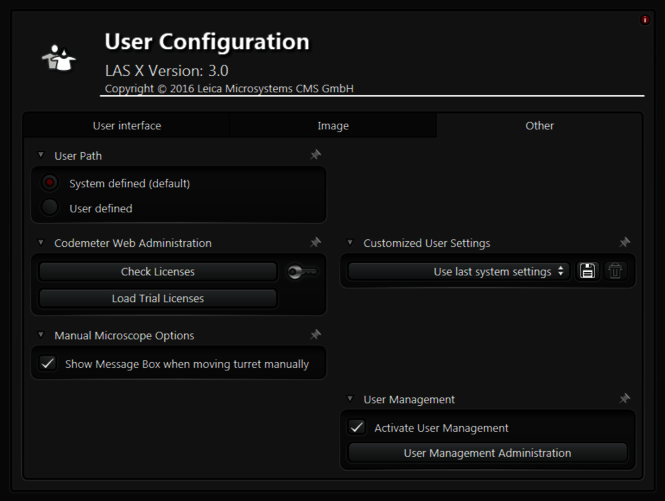

一个团队是由多个成员组成的,他们的显微镜技能掌握水平不同,要完成的具体任务也不同。

主管对此难以应对?当然不会!

无论是显微镜新手或专家,LAS X 令主管能够根据每个团队成员的技能水平和任务创建独立的用户配置文件,确保您的团队获得预期的可靠结果。

User configuration of LAS X software platform

LAS X 为各种专业应用提供一系列附加软件模块和专家级解决方案,因此您可以对显微镜系统进行量身定制,使其成为专用的高性能工具,以应对当前和未来挑战。

我们的全球应用专家团队非常乐意为您提供软件模块的良好选择建议。

了解我们的软件模块如何为您提供应用支持:

单张图像摄取和记录

2D 和 3D 模式下的摄取、测量与分析

金相学

LAS X software tools

Microscopy tasks in industrial applications such as quality control and quality assurance, failure analysis, research and development as well as materials science and forensics are varied and diverse. From image acquisition to reporting, software plays an integral part every step of the way.

To provide the specific software capabilities you need, Leica Microsystems offers modules that complement the LAS X software. Choose from a range of software modules – see below for more information on what our modules can do for you.

If you require additional information or advice, please so not hesitate to contact us.

| Name | Description |

| LAS X User Management | Create user groups with different access levels. Allow or restrict individual functionalities for respective access levels. |

| LAS X Extended Annotation | Annotate your images with text in various fonts and colors, graphics, or measurements. |

| LAS X Measurements | Measure parameters such as length, area, diameter, angle, or perimeter of objects you mark with adjustable tracing lines, drawing directly in the live images. Add labels for easy analysis. Apply measurements to several images to determine statistical trend and compare data in measurement templates. Apply long-distance measurements that span more than a single field of view. |

| LAS X Reticule | Display digital reticules, such as grain size, lines, circles, cross hairs and counting grids, on real-time images as electronic overlays for inspection, measurement, point counting, and comparison. Unlike eypiece reticules, digital reticules adjust to the magnification or zoom of the microscope. |

| LAS X Live Stream Movie | Capture images at set time intervals automatically to create movies to stream. Download as individual images or AVI files. |

| Name | Description |

| LAS X Live Image Builder | Create images that are bigger than a single field of view. Obtain a single in-focus image, if shallow depth of field provides only a partly focused image. |

| LAS X Z-Control & SW Autofocus | Create a single sharp image by capturing a stack of images at different focus positions and combining them automatically into an Extended Depth of Focus (EDOF) image. |

| LAS X Extended Depth of Field | Create sharp 2D images from several partially in-focus images. In connection with the 3D Surface Viewer, creation of 3D images is also possible. |

| LAS X Stitching | Create 2D images from multiple tiled images captured automatically. Obtain a spiral scan to capture only the region which interests you most. Single images can be retreived and analyzed with LAS X 2D Analysis. |

| LAS X 3D Surface Viewer | View 3D surfaces created from LAS X Extended Depth of Field. |

| LAS X 3D Surface Measurements | Measure 3D surfaces created from LAS X Extended Depth of Field in the LAS X 3D Surface Viewer. |

| Name | Description |

| LAS X Nodular Cast Iron Expert | Assess cast iron, adhering to industry standards including ASTM E247, ISO 945-2 and JIS5502. Use this software module for ductile irons to identify graphite nodules and place them into shape and size classes. Assess the ferrite and pearlite content and combine the results from these separate analyses. |

| LAS X Decarburisation Expert | Identify and analyse the depth of decarburisation in non- or low-alloyed steel. Automatically calculate the functional decarburization depth as a function of the amount present in the unaffected interior and your product specifications. |

| LAS X Metallography Toolbox | Assess, analyze, and measure metals, alloys, layers and coatings, adhering to laboratory requirements by incorporating analysis methods utilized in industry standards. Document your results in a Microsoft Excel report. |

| LAS X Grain Expert | Evaluate the properties of materials by analysing grain size to help determine the characteristics of the final product. The incorporation of industry standards ensures your analyses conform to your laboratory requirements. |

| LAS X Phase Expert | Measure multi-phase microstructures indentified by their distinctive color or contrast in materials and metallurgy laboratories. For example, reflectivity of components in oil-shale; polarisation colors of constituents in a thin rock section for modal analysis. Determine the occurrence of these phases with reference to the overall image or to one of the selected phases. |

| LAS X 2D Analysis | Detect, measure, and evaluate features and particles of powders, fiber cross-sections, pigments using a wide range of parameters. Use histograms, pie charts and statistics to illustrate results that can be exported to Microsoft Excel. |